P.series

P.search

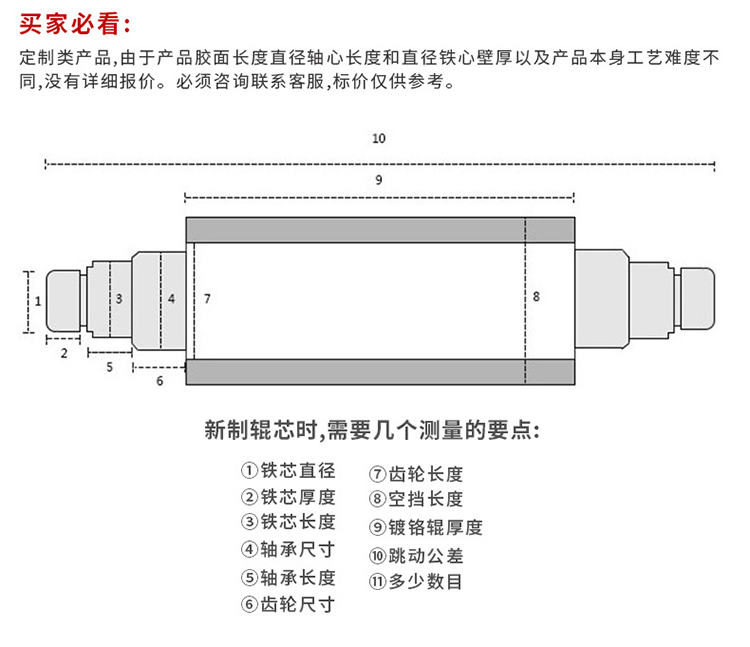

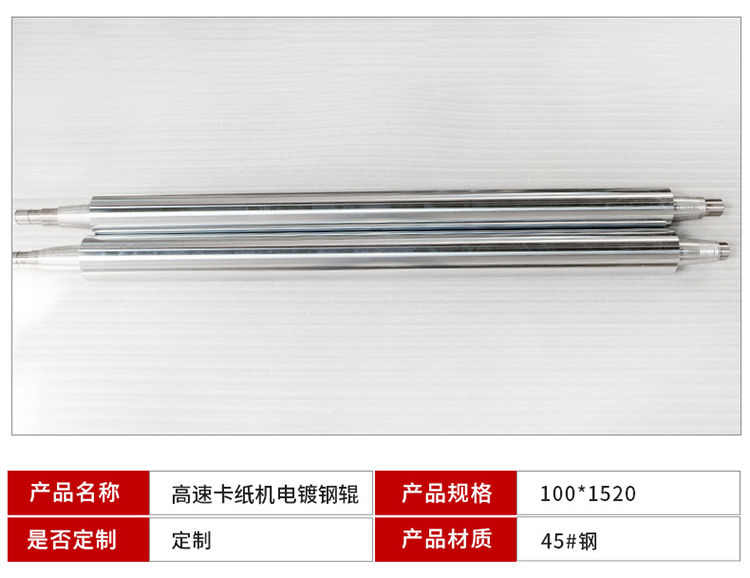

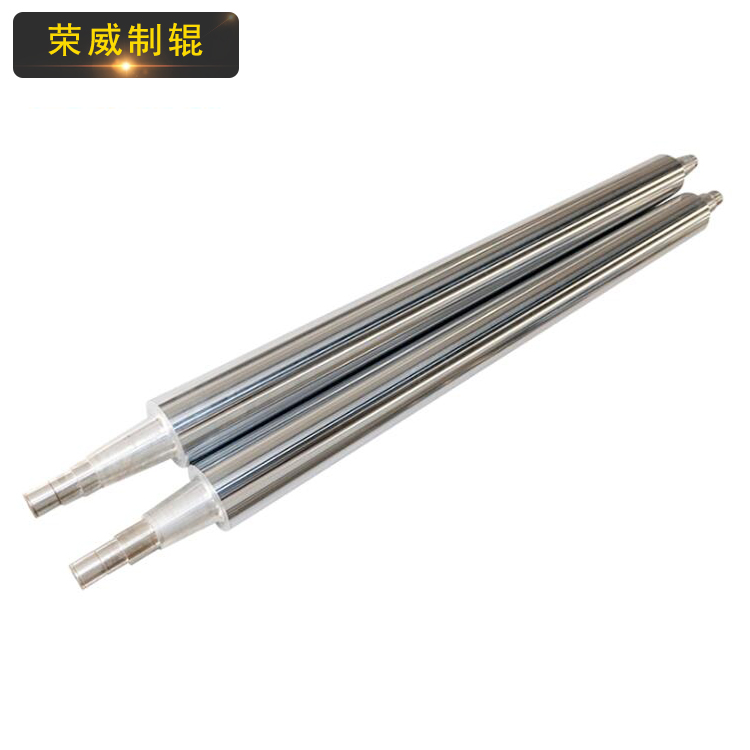

Application fields of electromagnetic heating roller: plastic sheet, sheet, film, paper, leather, cloth, rubber, anti-counterfeiting laser materials, stamping, textile, printing and dyeing, metal, non-woven materials, electronics and other industries calendering, calendering, composite, peritoneum, drying, pre-heating, embossing, embossing and so on. 1) material processing: select high-quality 45 # steel, alloy steel, high-quality steel, heat treatment process quenching and tempering, stress, quenching. The wall thickness of roller inner wall is uniform, and the hardness can reach HRC55 ~ 58 after quenching. 2) internal structure: from the inside to the outside are the center shaft, the heat insulation layer, the heating layer, the radiation layer, the insulation layer, the reflection layer, the high-temperature coating layer and so on. 3) heating method: electromagnetic induction heating, energy saving efficiency of 50-70% , electromagnetic induction heating roller surface temperature can reach 400 ° C or more. Surface treatment: hard chromium plating, spraying ceramic or tungsten carbide, after fine grinding, grinding and polishing treatment, roughness RA0.01(finish 14) . 5) machining precision: the temperature difference of roller surface ≤ ± 1 ° C, thermal deformation ≤0.01 mm, straightness, jumping, coaxiality ≤0.005 mm features: electromagnetic heating roller has many advantages, such as high temperature control precision, good temperature uniformity, fast temperature rising and cooling speed, easy maintenance, low energy consumption, safety, environmental protection and no pollution, etc. .